Aluminium Coil – Durable & High-Quality Solutions

Aluminum alloy coil is a highly versatile material and can be clearly classified by alloy series, with each category designed for specific applications, which helps search engines better understand content structure and improves Google indexing. 1xxx series aluminum coil (pure aluminum) features excellent corrosion resistance and high thermal conductivity, and is widely used in insulation jacketing, chemical tanks, and food packaging. 3xxx series aluminum coil, such as 3003 and 3004, contains manganese and offers good formability and cost efficiency, making it suitable for roofing sheets, wall cladding, heat exchanger fins, and household cookware. 5xxx series aluminum coil, alloyed with magnesium, provides higher strength and outstanding resistance to seawater corrosion, and is commonly applied in marine engineering, transportation, pressure vessels, and fuel tanks. 6xxx series aluminum coil, combining magnesium and silicon, balances strength and machinability, and is extensively used in aluminum profiles, window and door systems, curtain walls, and solar mounting structures.

By classifying aluminum coils based on alloy composition and end-use performance, buyers can quickly select the right material for construction, automotive, packaging, and energy industries. For more technical standards, you may refer to the Aluminum Association and the Wikipedia aluminum alloy overview .

Parameter |

Range / Options |

Thickness |

0.2mm – 3.0mm |

Width |

1000mm – 1600mm |

Surface Finish |

Mill Finish, Pre-painted |

Alloy |

1100, 1060,3003, 5005, 5052,6061,7075etc. |

Temper |

H14, H16, H18, H24 |

Mechanical Strength |

70–180 MPa |

Series of Aluminium Coils

1100 Aluminum Coil

1060 Coated Aluminum Coil

3003 Aluminum Coil

6061 Aluminum Coil

5005 Aluminum Coil

5052 Aluminum Coil

3104 Aluminum Coil

7075 Aluminum Coil

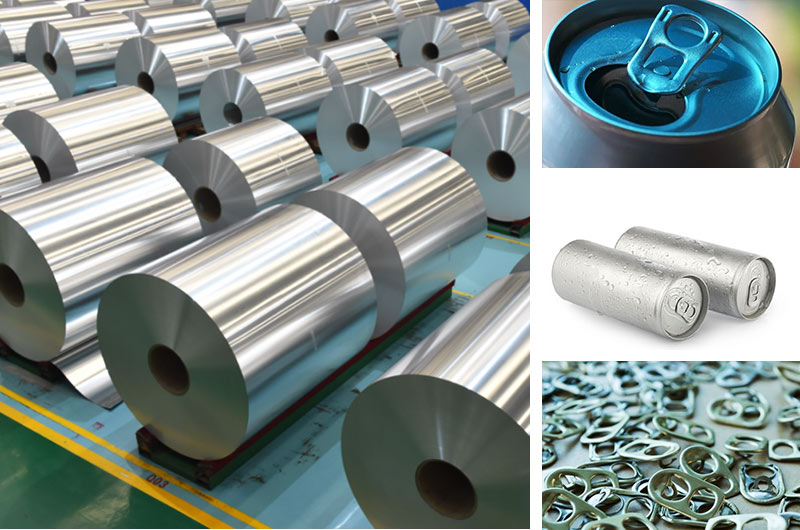

Applications of Aluminium Coil

3004 3104 aluminum coil strips for can body

3104 belongs to the Al-Mn alloys category. The addition of the main alloying element, manganese (Mn), enhances the mechanical properties of the alloy without compromising its corrosion resistance.

5052 5182 aluminum alloys are the most widely used materials for can lids.

5182 aluminum alloy is the most representative material for pull-tab manufacturing. is

Aluminum curtain wall system

Aluminum curtain wall systems offer excellent weather resistance, thermal performance (when combined with thermal breaks), sound insulation, and energy efficiency. They are widely used in office buildings, shopping malls, airports, hotels, and landmark architectural projects, supporting modern, sustainable, and visually striking building designs.

Aluminum Ceiling system

A ceiling system offers key advantages such as lightweight strength, corrosion resistance, and long service life. Aluminum ceiling systems provide a modern appearance with flexible designs, easy installation, and convenient access to lighting and HVAC systems. They are fire-resistant, low maintenance, and environmentally friendly, making them ideal for commercial and public buildings.

Why Choose Our Aluminium Coil ?

Features: Aluminum Alloy material can be completely recycled and reused, safe and environmental protection, no pollution, long service life.Also it can be excellent resistance to corrosion, moisture, UV exposure, and temperature changes, ensuring stable mechanical properties and surface quality over time

Wide Range of Uses: aluminium coils are widely used in construction (roofing, curtain walls, ceilings), packaging (can bodies, caps, foil stock), transportation (automotive and marine components), and industrial fields (insulation, heat exchangers, chemical equipment).

Aesthetic Appeal: aluminium coils are available as mill finish, color-coated, anodized, embossed, and stucco embossed surfaces. These finishes provide different visual effects and surface protection to meet decorative and functional requiremen

Standard Colors

We can customize the color according to your sample, the following colors are just examples.

Polar White

Country Red

Emerald Green

Koko Brown

Aged Patina

Dove Gray

Evergreen

Hartford Green

Hemlock Green

Sage Green

Sierra Tan

Solar White

Stone White

Surrey Beige

Matt Colors

We can customize the color according to your sample, the following colors are just examples.

Matte Burnished Slate

Matte Charcoal Gray

Matte Colonial Red

Matte Mansard Brown

Matte Musket Gray

Matte Regal White

Matte Slate Gray

Matte Zinc Metallic

Frequently Asked Questions

1.How do you control thickness tolerance of aluminium coils?

A: Thickness is controlled through advanced rolling mills and online gauge control systems. Typical tolerance complies with ASTM and EN standards, and tighter tolerances can be provided upon request.

2.What is the difference between H14, H24, and H32 temper?

H14 indicates strain-hardened aluminium, H24 is strain-hardened and partially annealed for better formability, while H32 offers a balance between strength and corrosion resistance, commonly used for construction applications.

2.What is your minimum order quantity (MOQ)?

MOQ depends on alloy and specification. Please contact us for detailed information.