Factory Profile

As a modern steel coil factory in China, we operate advanced production lines capable of manufacturing PPGI, GI, GL and pre-painted steel coils in widths of 800–1800mm and thicknesses from 0.2–3.2mm, with an annual capacity of 150,000 tons. Our focus on precision manufacturing, corrosion-resistant coatings and uniform surface quality ensures durable steel coils for construction, industrial, automotive and roofing applications. Equipped with automated machinery and strict quality monitoring, we provide efficient and professional coated-steel production for global buyers.

Our Annual Production Capacity

500,000 Tons

Cold Rolled Steel Coil

300,000 Tons

Galvalume Steel Coil

350,000 Tons

Galvanized Steel Coil

250,000 Tons

Prepainted Steel Coil

Introduction of production equipment

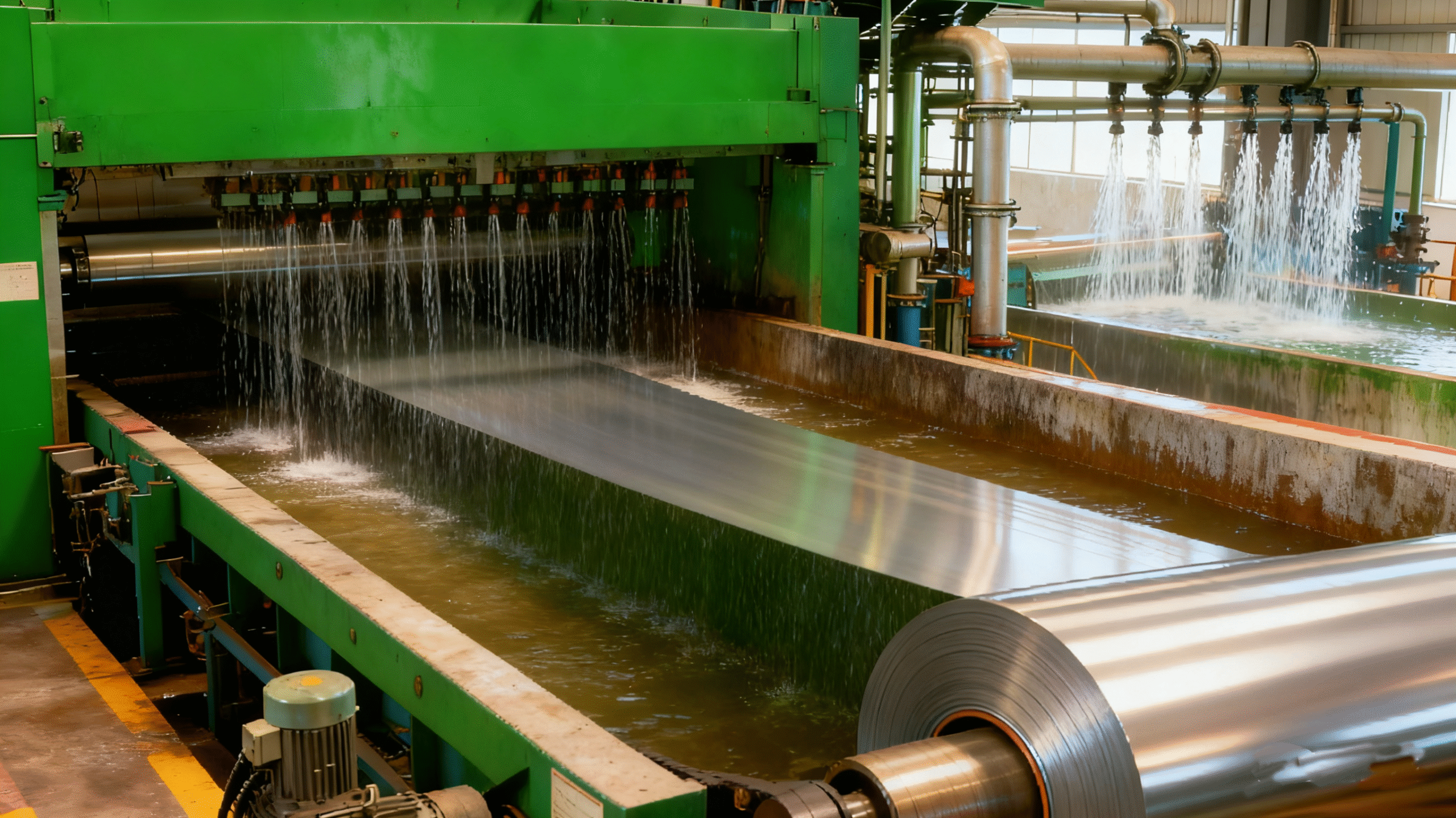

Pickling Steel Production Line

Our acid pickling lines are designed to handle steel coil widths from 600mm to 1600mm and thicknesses from 0.15mm to 2.0mm, with a production capacity of up to 100,000 tons per year. Engineered for PPGI, GI, GL, and cold rolled steel, these lines ensure uniform corrosion removal and superior surface preparation for downstream coating and processing. Choose our high-performance pickling line solutions for reliable, efficient, and consistent steel coil treatment

Advanced Cold Rolled Steel Production Line

Our cold rolling mill processes hot-rolled coils into high-precision steel with excellent dimensional accuracy and surface quality. With rolling widths from 700–1600mm and thickness capabilities from 0.12–2.5mm, the line delivers stable performance and uniform mechanical properties. Controlled by advanced automation and tension systems, it ensures consistent thickness reduction, improved strength, and a flawless surface—ideal for PPGI, PPGL, GI, GL, and automotive-grade steel application.

Galvalume Steel Production Line

Aluzinc (GL) production line applies a 55% aluminum-zinc alloy coating for superior corrosion and heat resistance. With coil widths of 700–1250mm and thicknesses of 0.16–1.2mm, the line offers stable coating performance ranging from AZ30 to AZ200. The alloy coating provides excellent barrier protection, making GL coils suitable for roofing sheets, wall panels, insulated panels and outdoor industrial applications. Advanced coating control ensures uniform adhesion and long-term service performance.

Galvanized Steel Production Line

Hot-dip galvanizing line applies high-quality zinc coatings that enhance corrosion resistance and durability. Supporting coil widths of 700–1250mm and thicknesses of 0.12–1.2mm, the line operates with an annual capacity exceeding 120,000 tons. Automated air knives ensure precise zinc-layer control, achieving consistent coating weights ranging from Z30 to Z275. This line is engineered for construction panels, appliance steel, structural components and general industrial use..