PPGI Coils Manufacturing | Full Process Coated Steel Production

PPGI production process details are key to consistent prepainted galvanized steel quality. Our standardized workflow uses scientific parameters and strict control. It covers core steps from substrate pretreatment to finish coat application. We deliver reliable PPGI that meets international standards for diverse industrial needs.

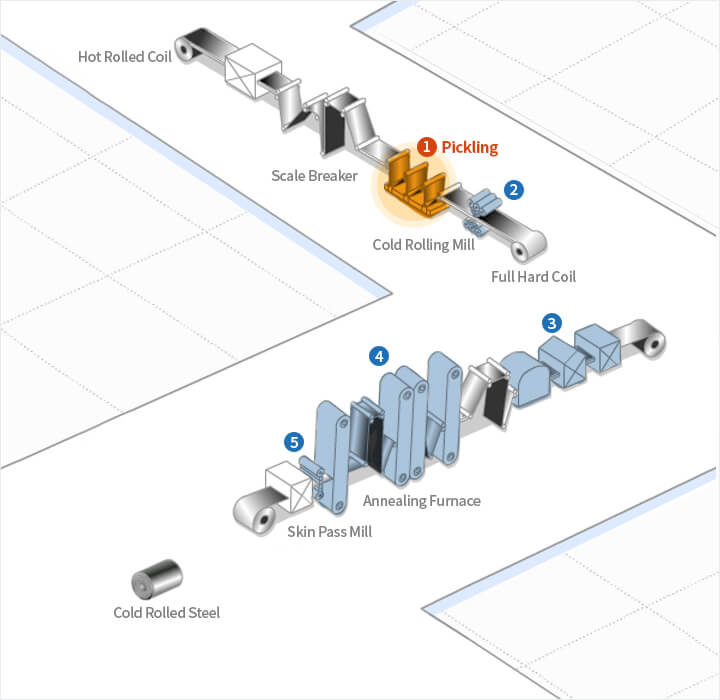

Step 1 –Cold Rolling – Foundation of High-Quality Substrates

Cold rolling is the foundational step of PPGI coils manufacturing, directly influencing the adhesion stability and precision of subsequent coated processes. We source premium hot-rolled steel coils as raw materials. Equipped with an advanced tension control system, we gradually reduce the raw material thickness from 2.0mm-6.0mm to the client-customized range of 0.12mm-2.0mm. High-precision roll processing ensures the steel coil surface is smooth and free of scratches, pitting, or other defects. Post-rolling, the coils are annealed in a bell-type furnace at 650℃-700℃ under inert gas protection, preventing deformation or cracking in later stages. The entire cold rolling process strictly adheres to international standards like ASTM A1008 and GB/T 708 .

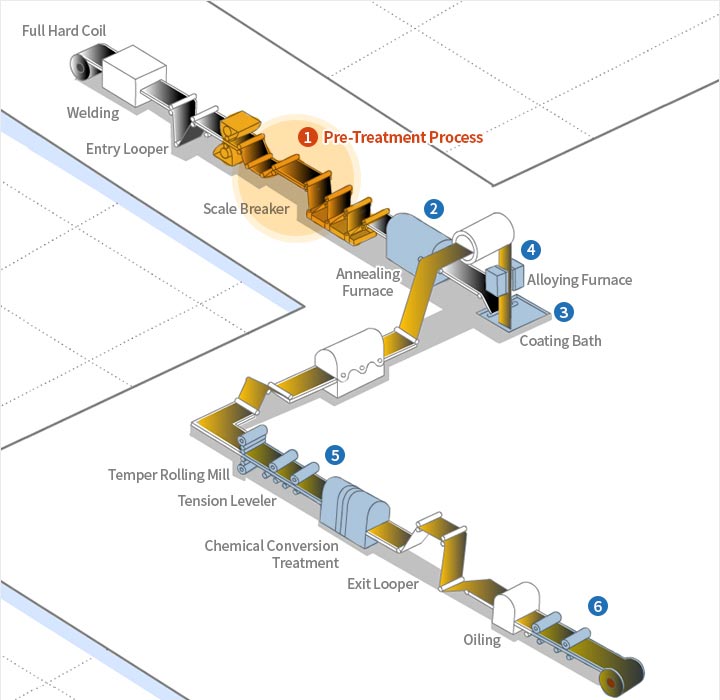

Step 2 – Galvanized and Galvalume Coil Production Process

Galvanizing is a key corrosion-protection process for steel coils, following a strict 5-step workflow. First, cold-rolled coils undergo Pre-Treatment Process (degreasing, pickling, fluxing) to remove surface impurities, ensuring coating adhesion. Next is Annealing—heated in a protective atmosphere to relieve stress and enhance ductility. Then comes Hot-Dip Galvanizing, with full immersion in a 450℃ molten zinc bath, air knife-controlled coating weight (60-275g/㎡). Post-dipping, Chemical Treatment (passivation) boosts corrosion resistance, followed by Inspection & Coiling to verify quality. Compliant with ISO 1461 and ASTM A123 it delivers high-performance galvanized substrates for industrial use.

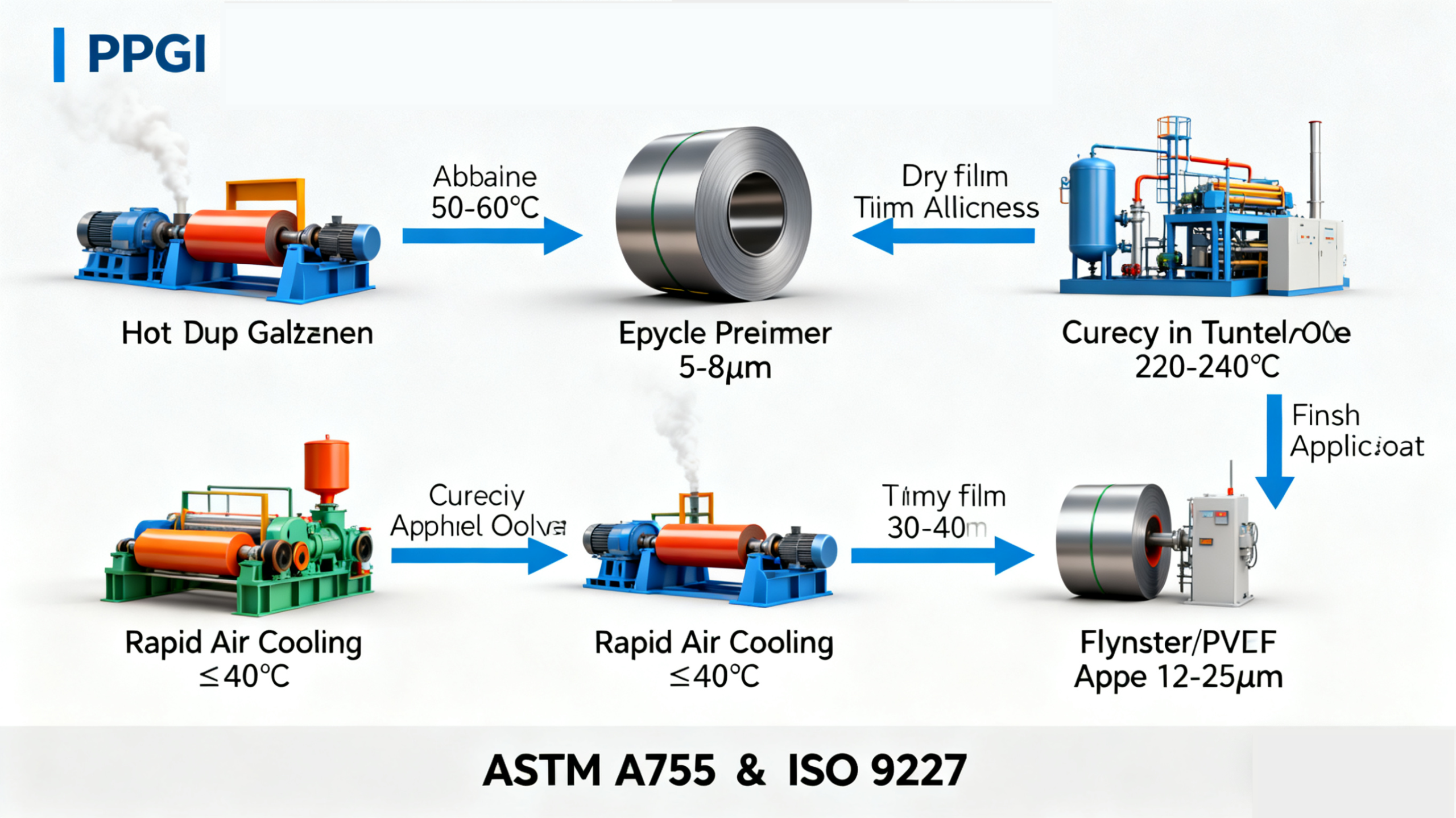

Step 3 – PPGI coils production process China

Starting with hot-dip galvanized coils, we degrease them through alkaline pretreatment (50-60℃, 3-5 minutes) to eliminate surface oils and oxides, ensuring coating adhesion. Next, a high-performance epoxy primer is evenly applied (dry film thickness: 5-8μm), followed by curing in a tunnel oven at 220-240℃ for 30-40 seconds to strengthen bonding. After curing, coils undergo rapid air cooling to 40℃ or below, then a durable finish coat (polyester/PVDF, dry film thickness: 12-25μm) is applied. Adhering to ASTM A755 and ISO 9227 standards, this process yields PPGI with excellent corrosion resistance, trusted for global construction, roofing, and industrial uses.